Product No:HY-E series

Brand:HONG YE SILICONE

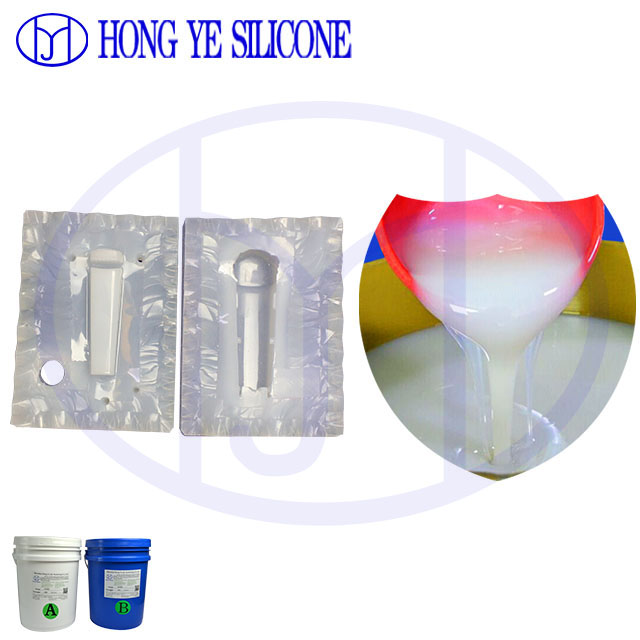

Product Usage: Rapid prototyping silicone generally requests high transparency so the silicone ba

INTRODUCTION

Silicone rubber for prototype is a two-component addition cure molding silicone material, generally requests high transparency, so the silicone base's color is clearer, which ensure the silicone rubber molds is tranparent enough to see the details inside.

Silicone base A and B are 1:1 mixture ratio, which can be cured at room temperature or at elevated temperature.

APPLICATION

Rapid prototyping silicone is used for casting epoxy resin, polyester resin, polystyrene, vinyl plastic, paraffin, large cement components, cultural stone, concrete, etc,

It is also widely used in precision die casting of automobile parts, ship parts, tire aluminum mold, tire mold, tire radial silicone mold, tire precision mold, etc.

ADVANTAGES

* Low shrinkage, no low molecule is rele-ased during crosslinking, so the volume remains unchanged, and the shrinkage is less than 0.1%

* It is not limited by the thickness of the silicone mold and can be cured deeply

* With excellent high temperature resistance, the temperature can reach 300-500 degrees

* Food grade, non-toxic and tasteless, passed FDA food grade certification

* High tensile strength, tear resistance, more molding times

* Good fluidity, easy to pour; can be cured at room temperature can also be heated curing, easy to operate

PRECAUTIONS

Mix the components A and B according to the weight of 1:1, and pour after vacuum defoaming. Room temperature (25 ℃) 30 minutes operation time, 3-4 hours fully cured; heating 60-120 ℃, can be fully cured in dozens of minutes.

The operation should be separated from the container that has used condensation cure silicone rubber, and the silicone rubber should be operated with tools that have not used condensation silicone.

Before use, a small test can be done on the mold seed to see if it will solidify, and then put into use.

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号