Product No:

Brand:

Product Usage:We provide addition cure silicone rubber for various kinds of applications and usage: 1. Food Grade Molding Silicone Rubbers, 2. Medical Grade Silicone Rubber, 3. Prosthetic Grade Silicone Rubber/ Life Casting Silicone Rubber,4. Sealing Potting Silicone Rubber, 5. Textile Coating Silicone Rubber, 6. Trademark making silicone rubber, 7. Foamed Liquid Silicone Rubber, 8. Silicone Leather, 9. Silicone for Making Printing Pad

As the global leading silicone rubber manufacturer with 18 years experience of silicone rubber’s production and 10 years silicone rubber’s exporting, Shenzhen Hong Ye Jie Technology is the BIGGEST EXPORTER of liquid silicone rubber of China in 2013, and our silicone rubber has been well-received by 138 countries and areas !

We provide addition cure silicone rubber for various kinds of applications and usage.

1. Food Grade Molding Silicone Rubber, it also includes the injection mold making silicone rubber, which are excellent for making molds for chocolate tray, jelly tray, sugar tray, candy molds, cake molds, ice cream, ice sculpture, butter, fondant, bread, baking and other food decorations. And this kind of silicone is also good for prototype design /rapid prototyping, diamond, jewelry and resin rhinestones molding.

2. Medical Grade Silicone Rubber which is also kind of human grade silicone, which are used for making silicone nipple, silicone foot health products and silicone chiropody’s products, such as silicone shoe insole, heel cups, toe spreader and silicone child toys, silicone baby doll which are safe for baby sucking, tiny silicone animal, silicone sex doll such as silicone clone dildo, artificial dildo, silicone penis, silicone vaginal vibrator, silicone vagina and so on.

3. Prosthetic Grade Silicone Rubber/ Life Casting Silicone Rubber which is also kind of life casting silicone rubber, Skin safe silicone rubber, it’s suitable for making human body molds and silicone dummies, silicone organs, silicone mask, silicone prosthesis, silicone breast pad/ bra pad, shoulder pads, silicone artificial limbs, silicone simulated robot and so on, and peoples always like flesh stone silicone rubber.

4. Sealing Potting Silicone Rubber, which is called jelly silicone rubber and flume sealing silicone rubber, it’s used for potting the surface of electronics such as PC (poly-carbonate), PP, ABS, PVC, metal; and encapsulating the flume and sump, with the purpose of electronic insulation, heat-insulated, waterproof and bonding, outdoor protection and technique protection.

5. Textile Coating Silicone Rubber, which is also a kind of heat transfer printing silicone rubber, mesh printing silicone rubber, screen printing silicone rubber. It’s specially used for skid-proof, water-proof and insulating purpose of frill, underclothes, clothes, socks, swimming cap which are made cotton fabric, polyester-mixed cotton cloth, nylon cloth, flax, woolen, lace, conveyer belt and so on.

6. Trademark making silicone rubber, which is used for making silicone badge, silicone labels and logo, fabricated into trademarks by cloth pressing and leather pressing, Generally, it’s applied to the trademarks of jeans, shoes, toys, socks, knapsack, packsack and so on.

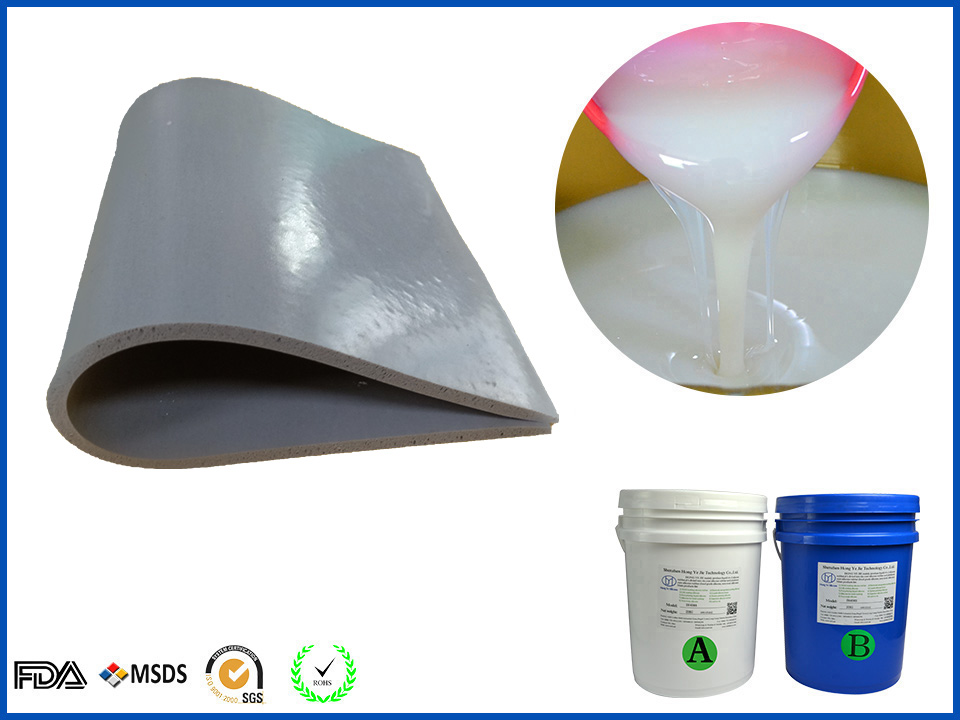

7. Foamed Liquid Silicone Rubber, which is always used as a filling material for PU products, silicone clone human, polyurethane furniture, since silicone rubber foam is very lightweight.

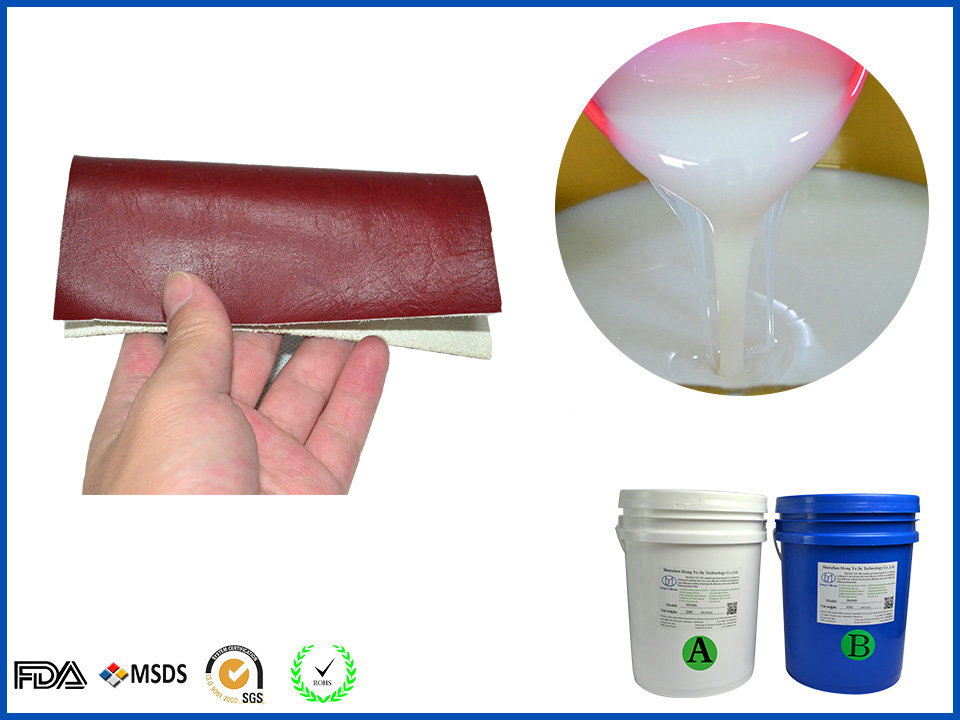

8. Silicone Leather, which is kind of new material in the world, it’s used as furniture leather, car leather, apparel fabric, shoe leather, luggage leather, bag and suitcases leather and so on.

9. Silicone for Making Printing Pad: Which is applicable to produce silicone printing pads. So friends, if you are interest in our mold making silicone rubber / casting silicone rubber, we welcome you to negotiate with us. Thank you.

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号