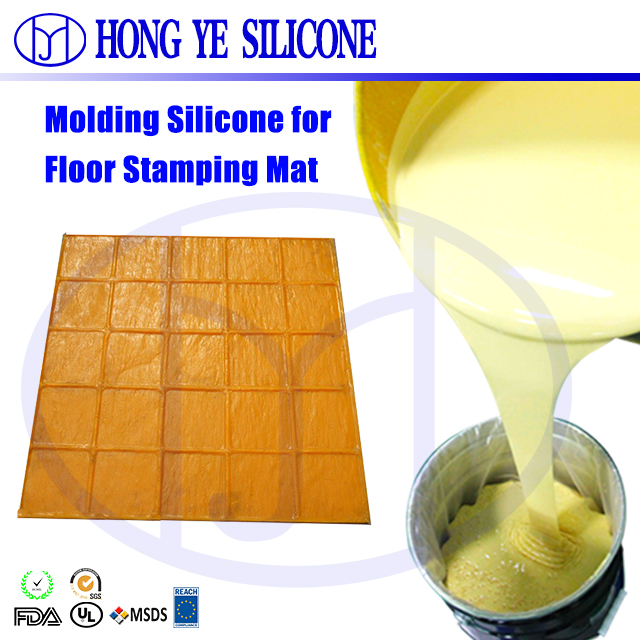

Product No:HY-6 series HY-E series

Brand:HONG YE JIE

Product Usage:HONG YE JIE provides two kinds of silicone rubber for concrete precasting, one is platinum cure silicone, another one is tin cure silicone.

Tin cure silicone is industry grade, it's not only suitable for precasting concrete, also suitable for many products' dulpication in industry.

CONCRETE PRECAST SILICONE DESRIPTION

Concrete precast silicone rubber is kinds of two part silicone rubber in addition cure silicone with mixing ratio of 1:1 or 10:1 or condensation cure silicone with mixing ratio of 100:3, which can cure at room temperature and suitable for both pouring molding and brushing molding.

CONCRETE PRECAST SILICONE APPLICTION

HONG YE JIE provides two kinds of silicone rubber for concrete precasting, one is platinum cure silicone, another one is tin cure silicone.

Tin cure silicone is industry grade, it's not only suitable for precasting concrete, also suitable for many products' dulpication in industry.

Platinum cure silicone is food grade feature ,edible ,friendly Environment protective,so it be widely used in making food grade mold ,such as jelly tray,chocolate tray.sugar tray, candy molds, cake molds, ice cream, ice sculpture, butter, fondant, bread, baking and other food decorations.

CONCRETE PRECAST SILICONE FEATURES

1.Environmentally, food-grade

2.An exceptional fluidity and good operability, easy to demold

3.Good tensile and tear strength

4.Outstanding bubble releasing

5.Non-deformation,Low shrinkage

6.Aging resistance ,high temperature resistance (220℃)

7.All hardness from 20 to 40 shore A

8..Non-adhesive surface, easy to clean, aging resistance and so on.

CONCRETE PRECAST SILICONE OPERATION

Firstly prepare the model mold or the product to be duplicated, take certain amount of the silicon rubber, add some solid curing agent(platinum cure silicone's mixing ratio is 1:1 or 10:1, tin cure silicone rubber's mixing ratio is 100:3), and mix evenly and they are ready for use. One pair of mold can be solidified and formed in 2-3 hours.

CONCRETE PRECAST SILICONE NOTES

If you choose addition cure silicone to precast concrete, kindly follow the tips below, because addition cure silicone rubber is a kind of platinum cure system ,which might cause uncure problem ,so :

1.Do not mix with liquid condensation silicone rubber or even the tool which used for condensation silicone

2.Do not mix with organic matter which contains N, S, P organics and ionic compound like Sn, As,Hg, Ph, 3.Do not add any pigment or powder into the addition cure silicone rubber without any testing to prevent uncure problem 4.Do not smoke when making the silicone mold.

CONCRETE PRECAST SILICONE SHELF LIFE

Twelve(12) months from date of shipment when stored under 25℃ in the original sealed packages at dry and cool places.

CONCRETE PRECAST SILICONE PACKAGE

1kg/jar, 5kgs/drum, 20kgs/drum, 25kgs/drum, 200kgs/drum and vacuumed packing is available.

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号