Product No:HY-E series

Brand:HONG YE JIE

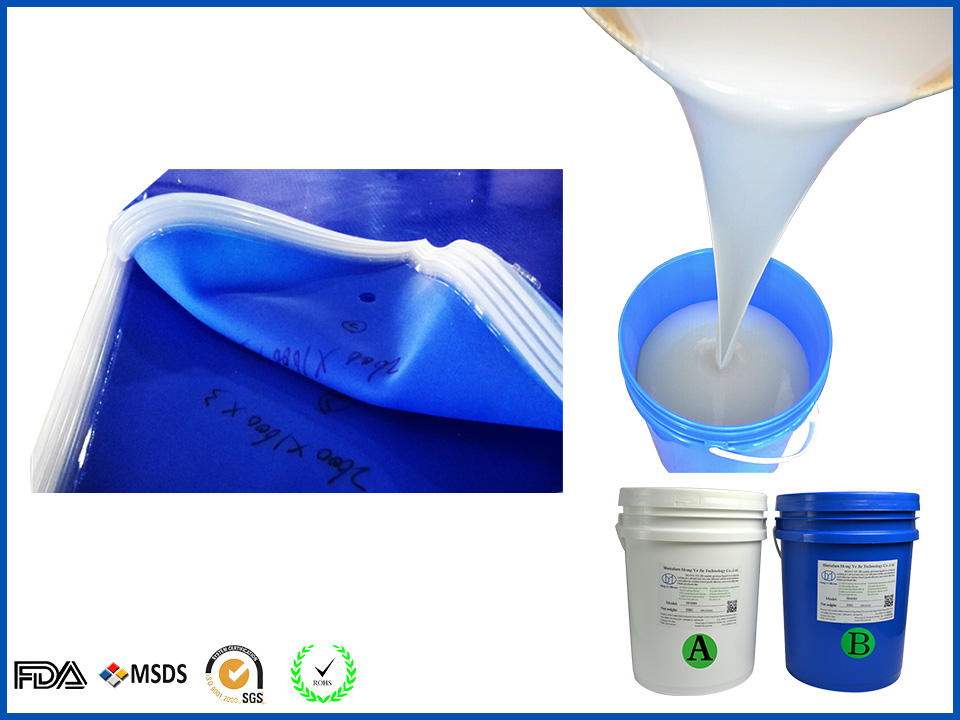

Product Usage:Sprayable silicone rubber is specially developed for vacuum bag for composites industry, it is a kind of room temperature vulcanized silicone rubber in addition cure type., Part A is a flowable liquid silicone, part B is the curing agent or catalyst . Which mainly suitable for spray by gun and spurting.

SPRAYABLE SILICONE RUBBER FOR COMPOSITES INDUSTRY DESRIPTION

Sprayable silicone rubber is specially developed for vacuum bag for composites industry, it is a kind of room temperature vulcanized silicone rubber in addition cure type., Part A is a flowable liquid silicone, part B is the curing agent or catalyst . Which mainly suitable for spray by gun and spurting.

SPRAYABLE SILICONE RUBBER FOR COMPOSITES INDUSTRY APPLICTION

Sprayable silicone also named as spurting silicone rubber,as for its low viscosity, good characteristic , it’s perfectly for composite industry for vacuum bagging.

It's also suitable for mold making for pouring molding of clay figurine, resin buddha , ceramic statues, polyurethane statuary, ceramic statues, artificial stone ,wax casting, gypsum, GRC, concrete product, resin products, Christmas ornaments, sculptures, figures etc.

SPRAYABLE SILICONE RUBBER FOR COMPOSITES INDUSTRY CHARACTERISTIC

1.Durable, much replication times

2.Suitable for brushing molding and pouring molding.

3. Good cut-growth resistance,Low shrinkage

4. Easily release air to avoid bubbles

5.Various hardness from 20 to 40 shore A

6. Excellent flexibility, easy to demould.

7. Room temperature cure in hours or Heat-accelerated cure

8.Equipped with RoHs REACH SGS ISO9001 ISO14001 etc. certificate

SPRAYABLE SILICONE RUBBER FOR COMPOSITES INDUSTRY OPERATION

1.Firstly prepare the model mold or the product to be duplicated, take certain amount of the silicon rubber, add 2-5% curing agent, and mix evenly and they are ready for use. One pair of mold can be solidified and formed in 2-3 hours.

2.Secondly, pouring or brushing the liquid mixture into the original mold.

3.Thirdly, demould the silicone mold after 3-5 hours. Then the molding is done.

SPRAYABLE SILICONE RUBBER FOR COMPOSITES INDUSTRY NOTES

1.The curing rate of this product is closely relevant to the temperature. The higher the temperature is, the faster the curing speed become. Users can choose the curing agent according to the weather condition,and adjust the amount of the curing agent so as to reach the appropriated curing rate.

2.Normally, different silicone should be choosed according to different Clay Figurine's features,for example : - For products size (80cm-150cm), with intricate designs, 25 shore A is suitable. with simple designs, 30-35 shore A is suitable. - For products size (more than 150cm), with intricate designs, 25-28 shore a A is suitable. with simple designs, 35-40 shore A is suitable.

SPRAYABLE SILICONE RUBBER FOR COMPOSITES INDUSTRY SHELF LIFE

Twelve(12) months from date of shipment when stored under 25℃ in the original sealed packages at dry and cool places.

SPRAYABLE SILICONE RUBBER FOR COMPOSITES INDUSTRY PACKAGE

1kg/jar, 5kgs/drum, 20kgs/drum, 25kgs/drum, 200kgs/drum and vacuumed packing is available.

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号