Product No:HY-E series

Brand:HONG YE JIE

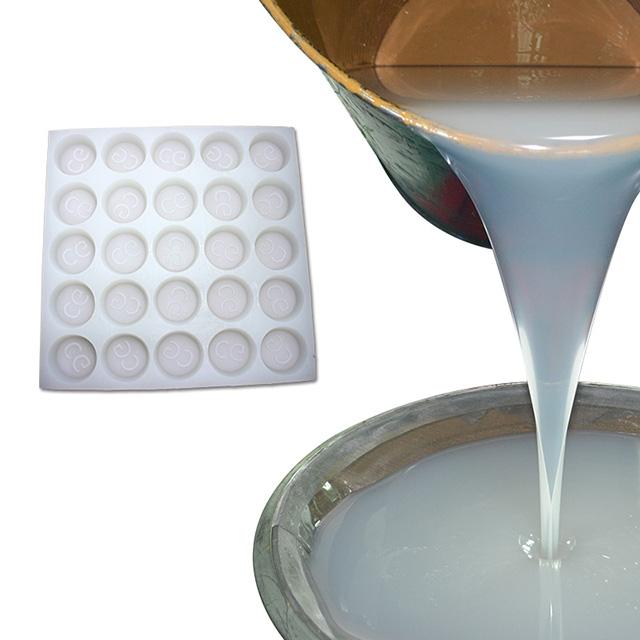

Product Usage:Molding Silicone for ice cream and ice tray is mainly used for making food models such as candy molds cake molds chocolate molds cupcake tray jelly traysugar crafts mouldscake decorationetc.as this food grade silicone is totally non-toxic and tasteless absolutely safe for food molding and baking. And it also widely used in life casting mold making with excellent tear and tensile resistance and environmental silicone such as silicone dummies silicone organs silicone mask silicone prosthesisfood grade silicone gasketetc.

DESRIPTION OF ICE CREAM MOLDING SILICONE FOR ICE TRAY

Molding Silicone for ice cream and ice try is a kind of good grade FDA liquid silicone rubber, it belong two-part addition silicone rubber, Part A is a flowable liquid silicone, part B is the curing agent. the mixed ratio is 1:1 or 10:1,mainly be suitable for making food products,with totally nontoxic, tasteless which reach FDA standard.

APPLICTION OF CREAM MOLDING SILICONE FOR ICE TRAY

Molding Silicone for ice cream and ice tray is mainly used for making food models, such as candy molds, cake molds ,chocolate molds, cupcake tray, jelly tray,sugar crafts moulds,cake decoration,etc.as this food grade silicone is totally non-toxic and tasteless, absolutely safe for food molding and baking. And it also widely used in life casting mold making with excellent tear and tensile resistance and environmental silicone, such as silicone dummies, silicone organs, silicone mask, silicone prosthesis,food grade silicone gasket,etc.

FEATURES OF ICE CREAM MOLDING SILICONE FOR ICE TRAY

- Environmentally, food-grade ,non-toxic

- An exceptional fluidity and good operability, easy to demold for food tray

- Aging resistance, the silicone mold can be kept in shape for long time

- Low Shrinkage:0.1%

- Certificates of FDA ROHS MSDS

OPERATION OF ICE CREAM MOLDING SILICONE FOR ICE TRAY

1.Firstly prepare the model mold or the product to be duplicated, take certain amount of the silicone rubber, add some solid curing agent(mixing ratio of 1:1 or 10:1), and mix evenly and they are ready for use. One pair of mold can be solidified and formed in 2-3 hours.

2.Secondly, pouring or brushing the liquid mixture into the original mold.

3.Thirdly, demould the silicone mold after 3-5 hours. Then the molding is done.

NOTES OF ICE CREAM MOLDING SILICONE FOR ICE TRAY

It’s a kind of platinum catalyst silicone rubber, so pls do not touch tin catalyst silicone, it means, everything touched tin cure silicone before shall be avoided to touch platinum catalyst silicone. The curing time is subject to the temperature, short time will be required under high temperature, long time will be required while the product with large thickness.

SHELF LIFE OF ICE CREAM MOLDING SILICONE FOR ICE TRAY

Twelve(12) months from date of shipment when stored under 25℃ in the original sealed packages at dry and cool places.

PACKAGE OF ICE CREAM MOLDING SILICONE FOR ICE TRAY

1kg/jar, 5kgs/drum, 20kgs/drum, 25kgs/drum, 200kgs/drum and vacuumed packing is available.

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号