Product No:HY-E HY-MJ series

Brand:HONG YE SILICONE

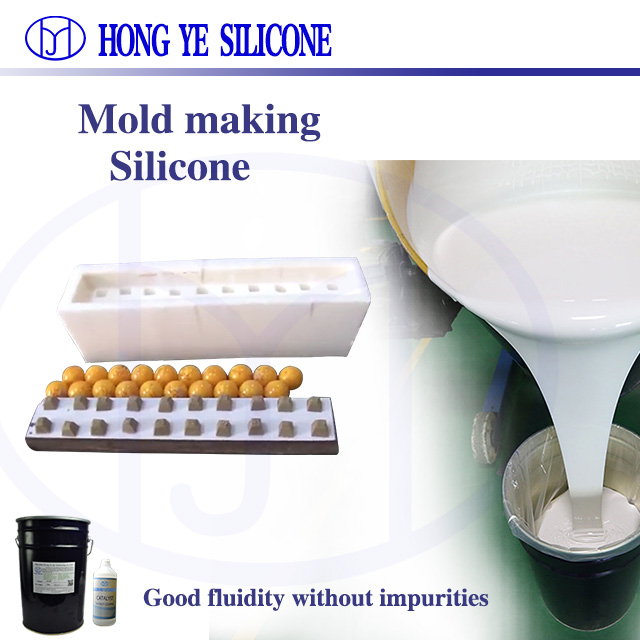

Product Usage: Addition cure molding silicone rubber is also a kind of platinum catalyst silicone rubber which is totally non toxic odorless and eco-friendly reaches the standard of food grade medical grade skin safe etc. It’s not only used for food molding such as chocolate sugar cake cup also suitable for molding building decorations arts and crafts sculptures furniture manual mold design shoe molding tire molding rapid prototype molding foundry casting lost wax casting artificial jewelries molding and so on.

ADDITION CURE SILICONE MOLDING RUBBER APPLICATION

Addition cure molding silicone rubber is also a kind of platinum catalyst silicone rubber which is totally non toxic, odorless and eco-friendly, reaches the standard of food grade, medical grade, skin safe etc. It’s not only used for food molding such as chocolate, sugar, cakec up, also suitable for molding building decorations, arts and crafts, sculptures, furniture, manual mold design, shoe molding, tire molding, rapid prototype molding, foundry casting, lost wax casting, artificial jewelries molding and so on.

ADDITION CURE SILICONE MOLDING RUBBER ADVANTAGES

- FDA certified, medical grade, totally nontoxic, odorless, harmless, and eco friendly

- The silicone mold is more flexible than resin mold, gypsum mold with softer hardness from 10-40 shore A.

- Low shrinkage less than 0.1%

- Longer service life (5 years) of this silicone mold than condensation cure silicone mold (1-2 years), with excellent UV-irradiation resistance and aging resistance

- High temperature resistance

- Environmental, odorless and nontoxic

- Good flexibility, permeability and insulativity

ADDITION CURE SILICONE MOLDING RUBBER DESCRIPTION

Our RTV-2 Molding materials are general called two-component room temperature vulcanization liquid silicone rubber with excellent fluidity and good operational performance. Add part B into part A, stir the mixture evenly, then pour or brush the liquid mixture to the mother mold, then after 2-6 hours, a flexible silicone rubber mold will be obtained a with resistance to deformation, high-temperature, acid and alkali and expansion.

ADDITION CURE SILICONE MOLDING RUBBER INSTRUCTION

If the customer wants to cast large size products with simple patterns , we should choose hard liquid silicone. On the contrary, if the mother mold is small size with fine details, we should choose soft rtv silicone.

- For products size (20cm-80cm) with intricate designs, 20-25 shore A is suitable. with simple designs, 25-30 shore A is suitable.

- For products size (80cm-150cm) with intricate designs, 25 shore A is suitable. with simple designs, 30-35 shore A is suitable.

- For products size (more than 150cm) with intricate designs, 25-28 shore a A is suitable. with simple designs, 35-40 shore A is suitable.

ADDITION CURE SILICONE MOLDING RUBBER NOTICE

1. In order to avoid no curing problem, it cannot mix with condensation cure silicone rubber, organic matter which is containing N, S, P organics and ionic compound like Sn, As,Hg, Ph. What’s more, please do not smoke when operating the food grade silicone rubber, otherwise, it will cause to no curing problem too.

2, The solidification of platinum cure silicone rubber is particularly affected by temperature, higher the temperature is, faster the curing time will be.

ADDITION CURE SILICONE MOLDING RUBBER PACKAGE

1 kg/jar, 5 kg/drum, 20 kg/drum, 200 kg/drum and vacuum package is available.

ADDITION CURE SILICONE MOLDING RUBBER SHELF LIFE

Twelve(12) months when stored under dry & cool place by original package under 25℃.

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号