Product No:HY-6,HY-E series

Brand:HONG YE JIE

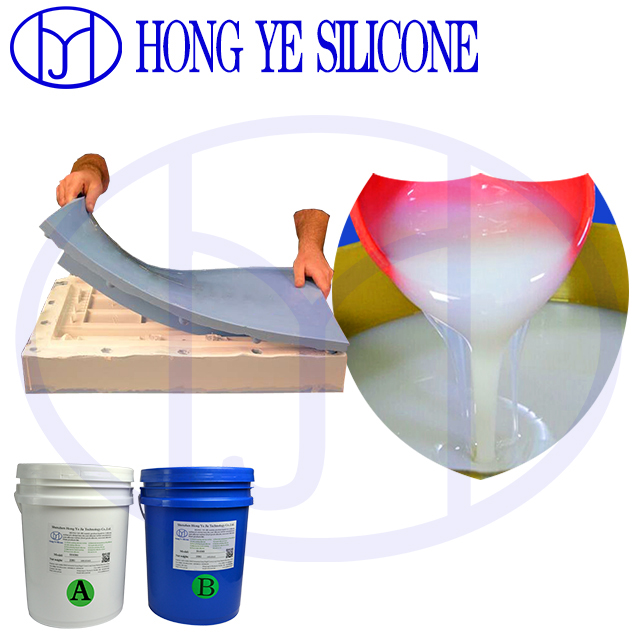

Product Usage:Low shrinkage silicone rubber for cement molding is a kinds of Two-parts silicone, it's perfect for cement, concrete stone, GRC and GFRC products' mold making, such as the flower pot, fountain, reinforced Plastic, garden decorations.Both tin cure silicone and platinum cure silicone rubber are suitable for replicating the silicone rubber mold for cement products, as long as it with good tear strength and tensile strength.

LOW SHRINKAGE SILICONE RUBBER FOR CEMENT CASTING DESRIPTION

Low shrinkage silicone rubber for cement molding is a kinds of Two-parts silicone, part A is flowable liquid silicon, part B is curing agent/ catalyst ,which gets cured at room temperature 25℃ within 3-6 hours or heating curing. This product is perfect for cement, concrete stone, GRC and GFRC products’ mold making, such as the flower pot, fountain, polyurethane wood imitation, reinforced Plastic, garden decorations, fiberglass product and other decoration industries.

LOW SHRINKAGE SILICONE RUBBER FOR CEMENT CASTING APPLICTION

Both tin cure silicone and platinum cure silicone rubber are suitable for replicating the silicone rubber mold for cement products, as long as it with good tear strength and tensile strength. That means, it's also suitable for resin arts, polyurethane arts, culture relic ,ornamental plaster, garden sculptures, fiberglass animal,GRC etc.

LOW SHRINKAGE SILICONE RUBBER FOR CEMENT CASTING FEATURES

1.High duplication times and no deformation

2. Excellent tear strength and tensile strength.

3.Good fluidity and good operability and good for both pouring method and pouring method.

4.Excellent flexibility and it’s easy to demould.

5.It gets cured at room temperature 25℃ within 3-6 hours.

6.Suitable hardness from 30 to 40 shore A

LOW SHRINKAGE SILICONE RUBBER FOR CEMENT CASTING OPERATION

Step 1. Prepare the original mold

Weight silicone & curing agent according to the mix ratio recommended,than remember to stir silicone & curing agent evenly, otherwise the silicon rubber will be partly solidified and bring problems in your final operation. What’s more, the finished molds will meet a short life.

Step 2. Vacuum pumping

This step takes less than 10 minutes. Otherwise, it will cause cross linking reaction, and no more further steps will be available.

Step 3. Pouring casting or Brush operation

Notes:1). For simple pattern products we suggest use pouring operation way, which will be very easy to operate and demould. Pourable silicone require light viscosity which will be easy to flow smoothly and easy to de-air .

2).For delicate pattern products we suggest use brushing operation way, which can copy the pattern exactly . Brushable silicone require high viscosity which won’t be easy to flow away and easy to brush .

Step 4. Demoulding

After 3-5 hours later, can demould the silicone mold, It’s will be better to demould after 24 hours

Note: We suggest to set the silicone mold for another 24 hours after demould before put into large production .

LOW SHRINKAGE SILICONE RUBBER FOR CEMENT CASTING NOTE

Normally, different silicone should be chosen according to different product's features,for example :

- For products size (20cm-80cm), with intricate designs, 20-25 shore A is suitable. with simple designs, 25-30 shore A is suitable.

- For products size (80cm-150cm), with intricate designs, 25 shore A is suitable. with simple designs, 30-35 shore A is suitable.

- For products size (more than 150cm), with intricate designs, 25-28 shore a A is suitable. with simple designs, 35-40 shore A is suitable.

LOW SHRINKAGE SILICONE RUBBER FOR CEMENT CASTING SHELF LIFE

Twelve(12) months from date of shipment when stored under 25℃ in the original sealed packages at dry and cool places.

LOW SHRINKAGE SILICONE RUBBER FOR CEMENT CASTING PACKAGE

1kg/jar, 5kgs/drum, 20kgs/drum, 25kgs/drum, 200kgs/drum and vacuumed packing is available.

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号