Product No:HY-6,HY-5,HY-Y8 series

Brand:HONG YE JIE

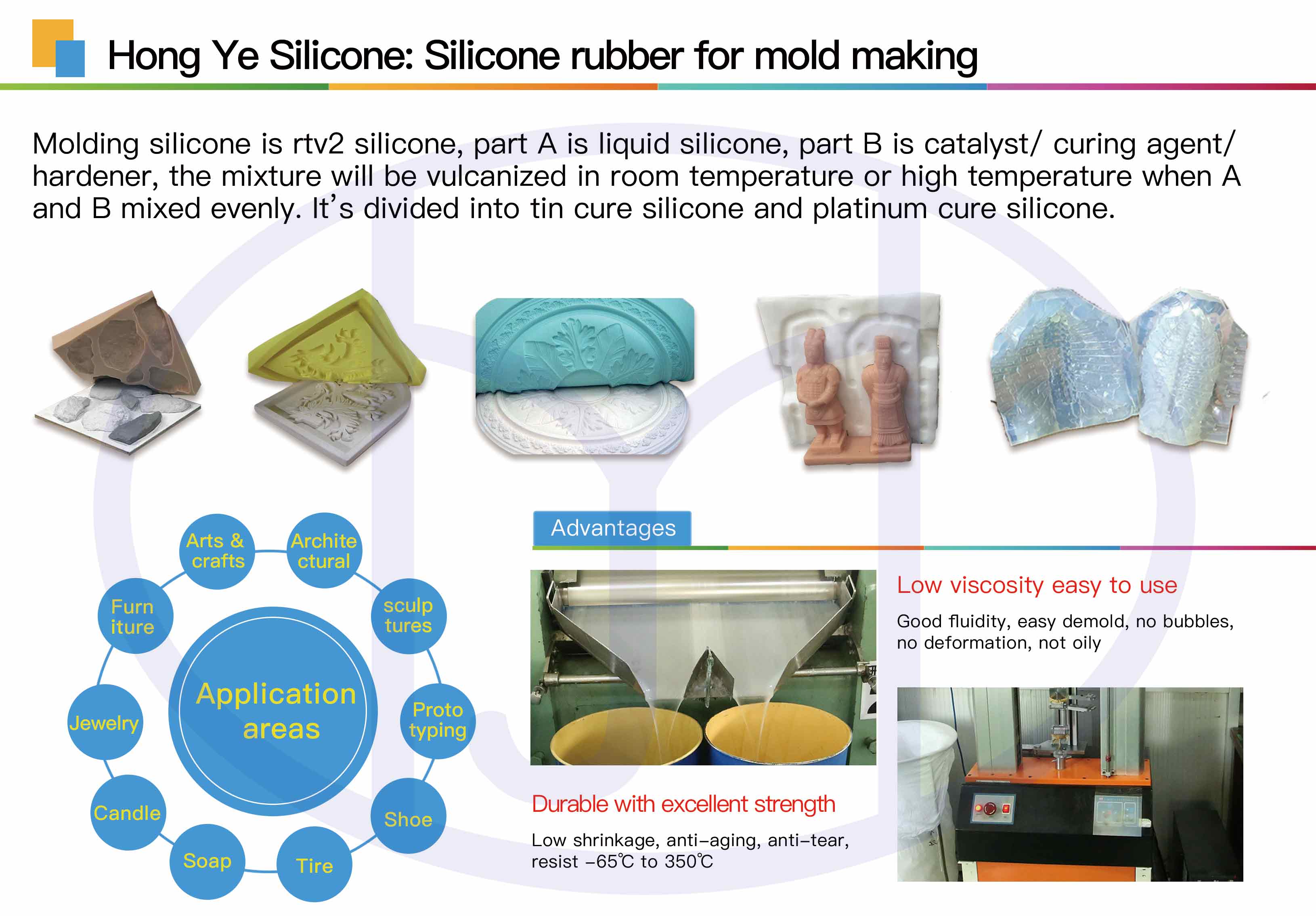

Product Usage:High strength silicone rubber is perfect for garden ornaments mold making, such as flower pot, wall decoration tiles, poly resin crafts, PU crafts, PU resin crafts ,gypsum crafts , unsaturated resin crafts, lighting and candles crafts, plastic toy , stationery gifts crafts industry, a large statue Buddha, relief, furniture, furniture decorative materials, statues Buddha, artifacts copied, building decoration materials, large-scale cement mold, artificial fossils Factory, Europe component factory, simulation landscapes, animals and plants sculpture, sandstone crafts and so on.

Introduction of high strength silicone rubber

High strength silicone rubber is perfect for garden ornaments mold making, such as flower pot, wall decoration tiles, poly resin crafts, PU crafts, PU resin crafts ,gypsum crafts , unsaturated resin crafts, lighting and candles crafts, plastic toy , stationery gifts crafts industry, a large statue Buddha, relief, furniture, furniture decorative materials, statues Buddha, artifacts copied, building decoration materials, large-scale cement mold, artificial fossils Factory, Europe component factory, simulation landscapes, animals and plants sculpture, sandstone crafts and so on.

Characteristics of high strength silicone rubber

1.High duplication times and no deformation

2. Excellent tear strength and tensile strength.

3.Good fluidity and good operability and good for both pouring method and pouring method.

4.Excellent flexibility and it’s easy to demould.

5.It gets cured at room temperature 25℃ within 3-6 hours.

6.Suitable hardness from 30 to 40 shore A

FAQ of high strength silicone rubber

1.Why will the silicone mold be reused only for a few times?

a. Adding too much silicone oil in to silicon rubber. Silicon oil is an additive which can destroy the molecular weight of silicone rubber and reduce the tension and tear strength.

b. Using the silicon rubber with a high hardness to make molds for small sized products with delicate and intricate designs or the silicon rubber with a low hardness to makes molds for large sized products with simple designs.

Notes: we should choose the silicon rubber specifically according to the requirements of our products to avoid this problem.

2.Why does the silicone mold get burnt out?

This consequence happens only because you have left out the important notes when using unsaturated resin materials to produce your products. The unsaturated resin produces great heat when added the curing agent. So you demould the resin product within 3 minutes can avoid this problem.

3.Why does the silicone mold appear to dry outside but wet inside?

Because molding silicone rubber is a kind of condensation silicone rubber, which get solidified after absorbing moisture from the air. In order to provide a significant shelf-life for the silicon rubber, we will dry out the water in the silicon rubber.

Solution: Add 0.1% water into the silicon rubber and Stir over a low speed briefly when you use it.

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号