Product No:HY-E series

Brand:HONG YE JIE

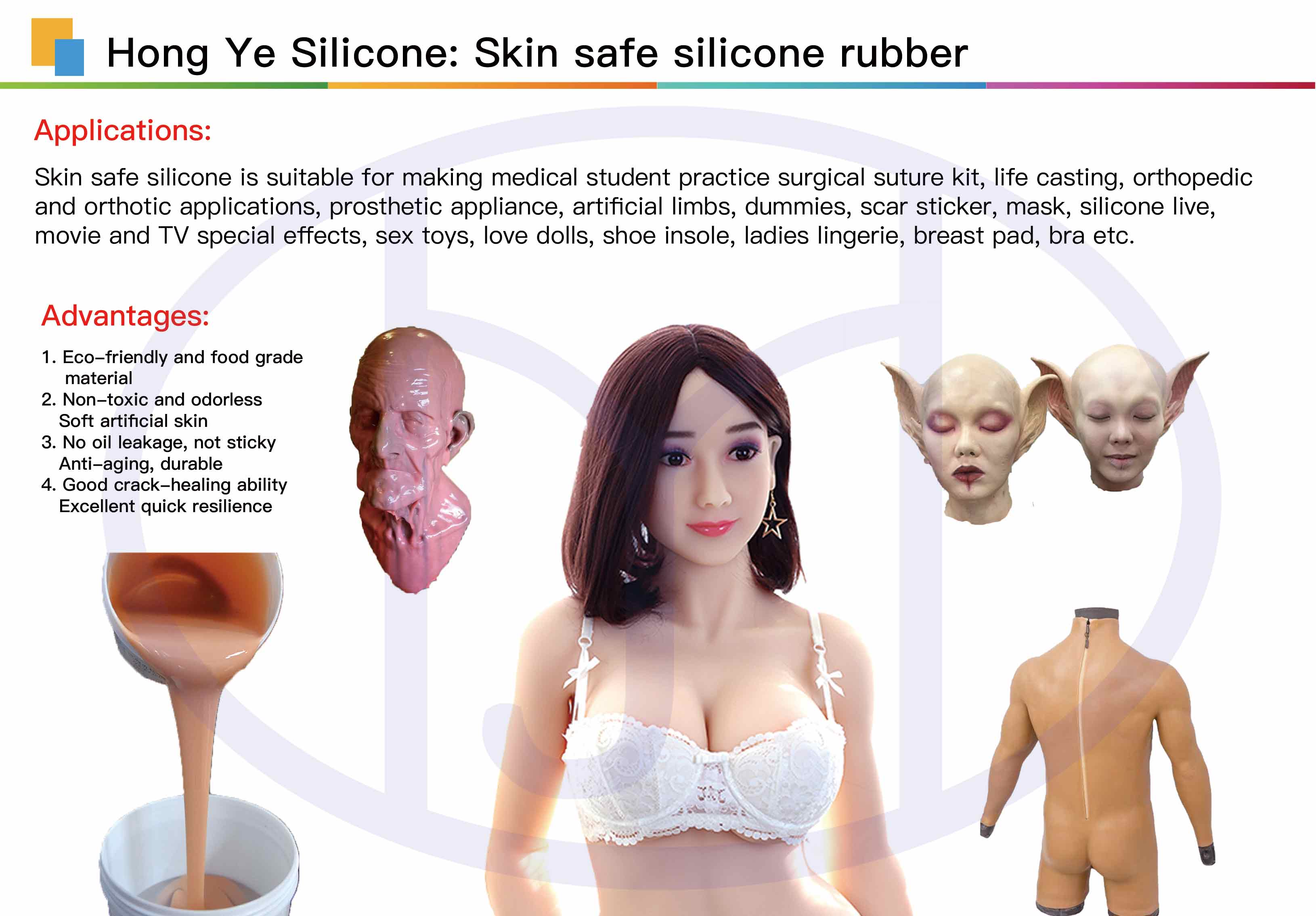

Product Usage:Toxic free silicone is also including medical grade silicone, which is suitable for making silicone soft cushions such as silicone shoe insoles, silicone breast pads, silicone bra, silicone toys, silicone prosthesis and other elastic and soft silicone products.

Applications of toxic free silicone rubber

Toxic free silicone rubber can be a mold making material for foods in a wide range of applications including ice cream moulds, fondant mold, ice mold, silicone cracker molds, Pathmate stone mold, cornices, balustrades, fountains, decorative garden articles, decorative stone molds, gypsum sculpture, etc.

Toxic free silicone is also including medical grade silicone, which is suitable for making silicone soft cushions such as silicone shoe insoles, silicone breast pads, silicone bra, silicone toys, silicone prosthesis and other elastic and soft silicone products.

Advantage of toxic free silicone rubber

* low shrinkage (less than 0.1% )

* high tensile and tear strength with high copy times

* easy to operation (mixing ratio at 1:1 )

* good fluidity easy for pouring operation ( in round 5000 cps )

* high temperature resistance in around 450- 500 centigrade

Packaging & Shipping of toxic free silicone rubber

1kg/drum; 5kg/drum; 20kg/drum; 25kg/drum; 200kg/drum.

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号