Product No:HY-6, HY-5, HY-E, HY-Y8 series

Brand:HONG YE JIE

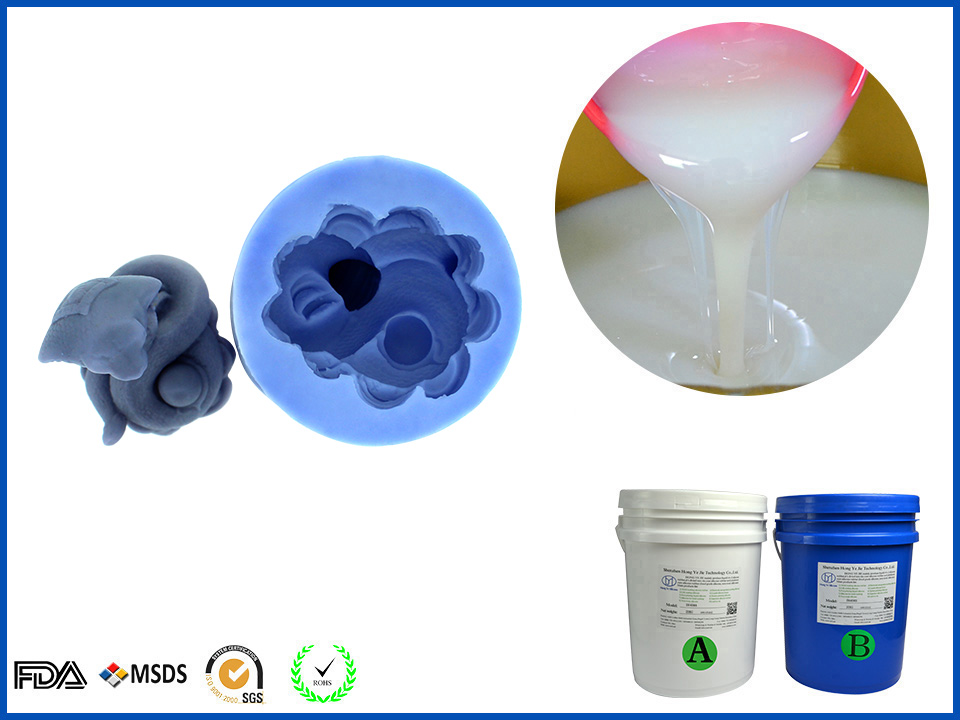

Product Usage: Resin sculpture mold silicone rubber includes condensation cure silicone rubber and addition cure silicone rubber,the former is traditional industrial silicone rubber that the mixing ratio is 100:5,the latter is very popular addition cure silicone rubber in the few years that is environmental ,non-toxic,tasteless and also named food-grade silicone rubber,its’ mixing ratio is 1:1 or 10:1, and 1:1 silicone is more popular.

DESCRIPTION

Resin sculpture mold silicone rubber includes condensation cure silicone rubber and addition cure silicone rubber,the former is traditional industrial silicone rubber that the mixing ratio is 100:5,the latter is very popular addition cure silicone rubber in the few years that is environmental ,non-toxic,tasteless and also named food-grade silicone rubber,its’ mixing ratio is 1:1 or 10:1, and 1:1 silicone is more popular.

For resin sculpture mold making,brushing mould is more popular.It is primarily due to the large size of resin sculpture and its pattern is delicate and intricate ,brushing mold can replica products completely.

For resin sculpture products with simple pattern,pouring mould is more suitable,which can not only replica patterns completely but also save operation time and artificial cost. Therefore,you can select suitable resin sculpture mold silicone rubber depends on your practical situation.

APPLICATION

Resin sculpture mold silicone rubber is primarily intended for all kinds of large, medium, small size resin model craft ornaments, craft sculpture, animal clay moulds, delicate fiberglass reinforced plastic sculpture, human sculpture,cartoon game characters model customize, traditional plaster statue, Guanyin plaster statue mould, clay, sculpture model, government building mold making and also used for delicate movie props, car, military mold making.

FEATURES

1.High temperature resistance,generally the temperature can reach 180-250℃.if special reagents are added,it can reach 300℃,which can solve the problem effectively that is resin products releasing a lot of heat to cause destroyed silicone mold.

2.No oil,the best of silicone rubber industry,prolong the silicone life.

3.The hardness,viscosity,operation time are available according to your requirements.

4.Lower shrinkage in silicone industry,more durable,high duplication times,non-deformation.

Silicone and Curing agent Reaction of Condensation Cure Silicone

1.The amount of curing agent is 1%,mixture is still flowable in 2.5 hours,demould after 6-8 hours.

2.The amount of curing agent is 2%,mixture is still flowable in 50-60 minutes,demould after 2-3hours.

3.The amount of curing agent is 3%,mixture is still flowable in 28-30 minutes,demould after 1.5-2 hours.

4.The amount of curing agent is 4%,mixture is still flowable in 10-15 minutes,demould after 1-1.5 hours.

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号