Product No:HY series

Brand:HONG YE JIE

Product Usage:Silicone rubber can maintain elasticity for a long time in the temperature range of 65 ~ 250 ℃ and has excellent electrical properties and chemical stability. It can resist water ozone and climate aging. In addition it has simple usage and strong process applicability.

Description of silicone

Silicone rubber can maintain elasticity for a long time in the temperature range of 65 ~ 250 ℃, and has excellent electrical properties and chemical stability. It can resist water, ozone and climate aging. In addition, it has simple usage and strong process applicability.

Application and Advantages of silicone

Silicone rubber is including food grade silicone, medical grade silicone, skin safe silicone and industry grade silicone, has quite wild applications, such as:

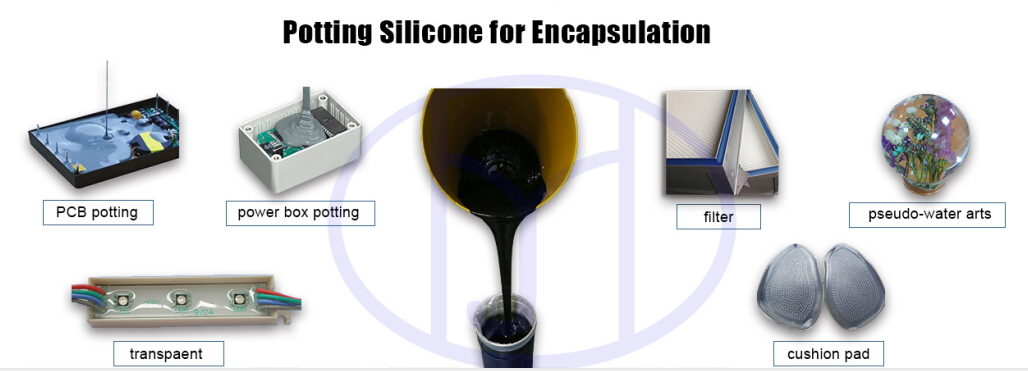

1. Silicone potting compound for electronic components, such as PCB, circuit board, transformer, connectors, LED, power supplies and so on, or as media for air filter

Advantages:

1) Good adhesion, flame retardant, waterproof, fire proof, insulation, moisture proof, quake-proof/ withstand vibration, thermal conductive, electrical conductive, Antistatic, excellent flow leveling, adjustable working time, good refracting, excellent electrical properties and so on.

2) Compared with epoxy resin, it has better modification ability and electrical insulation ability, high and low temperature resistance, climate aging resistance, ozone resistance, hydrophobia, non-flammability, non-toxic, non-corrosive and physiological inertia, etc.

3) Good cold and heat shock resistance, withstanding the cold and heat shock of - 60 C - 200 C, non-cracking, maintaining elasticity, sealing performance, moisture-proof/waterproof performance is superior.

4) After curing, it is an elastomer with good impact resistance, anti-ultraviolet and anti-atmospheric ageing weatherability, no exothermic heat during curing, little stress on electronic components, insufficient strength and low shrinkage.

5) It can be adjusted into flame retardant, insulating and conductive properties, with silicon-oxygen (Si-O) bond as the main chain structure, which is superior to other filling materials in life, poor adhesion and low strength.

6) It can be operated in all kinds of harsh environments without too much requirement for the environment (Moisture, salt fog, dust, vibration, heat, deep sea, cold, etc.).

2. Medical grade skin safe silicone for medical student practice surgical suture, TV and movie live, prosthetic, artificial limbs and dummies, sex toys and love dolls, orthopedic and orthotic, mask, scar sticker, shoe insole,breast pad, silicone bra and coating ladies lingerie,

Advantages:

1) Food grade, non-toxic, odorless, eco-friendly skin safe and body safe.

2) Soft and flexible, the simulation is very real

3) Excellent tear and tensile strength for good quality and durable

4) No sticky problem

5) Dry surface without oily problem

6) Low shrinkage

7) Good crack-healing ability

8) Wobbles very close to the real body

9) Excellent and fast resilience

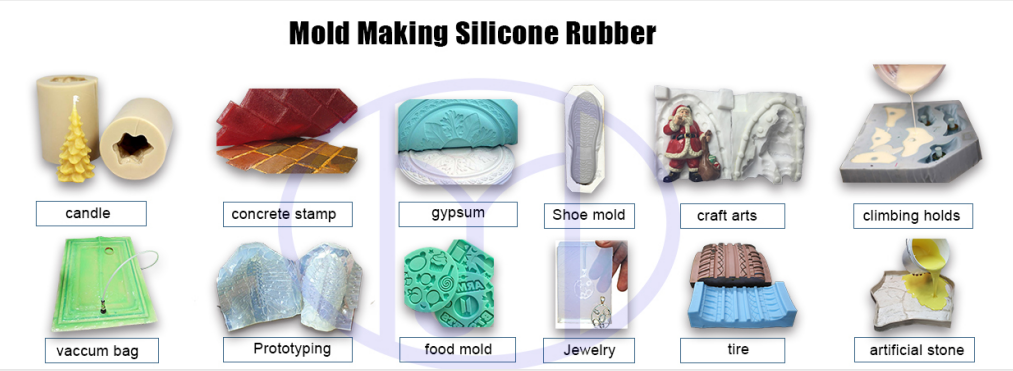

3. Mold making silicone rubber for reproducing and replicating art crafts, furniture, prototyping, architectural elements, garden ornaments, shoe, tire, soap, candle, jewelry, vacuum bag and so on, since molding silicone is suitable for casting resin, PU, PVC, polyester, gypsum, plaster, concrete, cement, stone, GRC, wax, jewelry and so on.

Advantages:

1) Flexible and low viscosity which will copy finest details and patterns from exquisite products.

2) Durable with good strength, top quality to guarantee molding times

3) Easily demolding

4) Not oily, no bubbles

5) Can resist high temperature 200℃ - 350℃, and low temperature -65℃

6) Low shrinkage less than 0.2%, platinum cure type is less than 0.1%

7) Aging resistance, acid and alkali resistance

8) Platinum cure silicone is food safe, skin safe, nontoxic, odorless

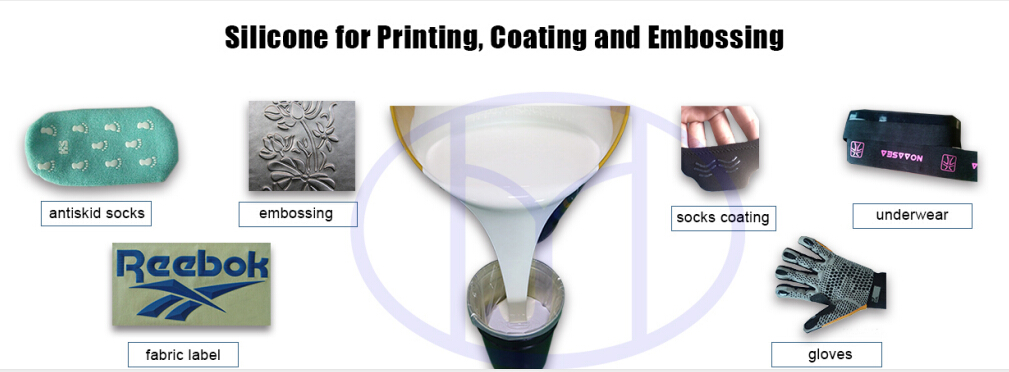

4. Textile coating silicone for mesh screen printing and heat transfer printing, such as coating fiberglass fabrics, and for embossing silicone for making silicone label,

Advantages:

1) Environmental protection/non-toxicity, food grade silicone

2) High viscosity, not easy to penetrate

3) Can set color (multi-layer color), do not fall off when set color, pattern is not single, can form different patterns, silicone printing trend leads the fashion field.

4) Various effects can be printed (bright or matte, round or right-angled effect, thick or thin, large or small patterns), strong stereoscopic effect, soft handle and strong adhesion.

5) High wear resistance, brightness and washability

6) Can firmly adhere to the surface of textiles, non-woven fabrics, dermis, imitation leather and other materials.

5. Silicone for coating leather, which is the perfect replacement for PU leather.

Advantages:

1) Food grade, non-toxic, is a much safer material than PU

2) No toxic gases are produced in the sun to damage health

3) Flame proof and fire proof

4) Solve the problem of firmness of leather and waterproof fabric effectively

5) The silicone leather’s surface is absolutely dry, no sticky problem

6) High wear resistance, brightness and washability

7) Super elasticity, in the normal range of elasticity of the fabric does not fall off, cracking.

6. Silicone foam for foamed sheet, foamed roll, sitting cushion, mattress, or as filling material for sofa, mannequin,

Advantages:

1)Uniform foaming pore and uniform pore size

2)Foaming multiple from 2 to 10 time, lightweight

3)Food grade

4)Much more environmental, nontoxic, odorless than sponge and PU.

5)Stable size, low shrinkage

6)Excellent strength with good quality

7)Can resist high temperature 200℃ - 350℃, and low temperature -65℃

8)Heat preservation, adjustable transmittance

9)Fire proof, flame retardant, electrical insulation

10)Aging resistance, acid and alkali resistance

7. Silicone for printing pad and tampo pad, such as for ceramic porcelain tableware, plastic toys and so on.

Advantages:

1) The liquid silicone very delicate without any impurities or particles.

2) Excellent resilience, flexible

3) Durable, the printing times can more than 10000 times

4) Good oil absorption effect

5) The pattern is printed with great clarity and completeness.

6) Keep good quality even though 200%-300% silicone oil added

8. Silicone gel with super soft hardness,

Advantages:

1) Super soft

2) Perfect sealing, bonding, filling, potting and encapsulating material

3) Food grade, non-toxic

4) Good crack-healing ability

5) Excellent and fast resilience

6) Strong adhesiveness

7) Wobbles very close to the real body

Why chose Hong Ye Silicone:

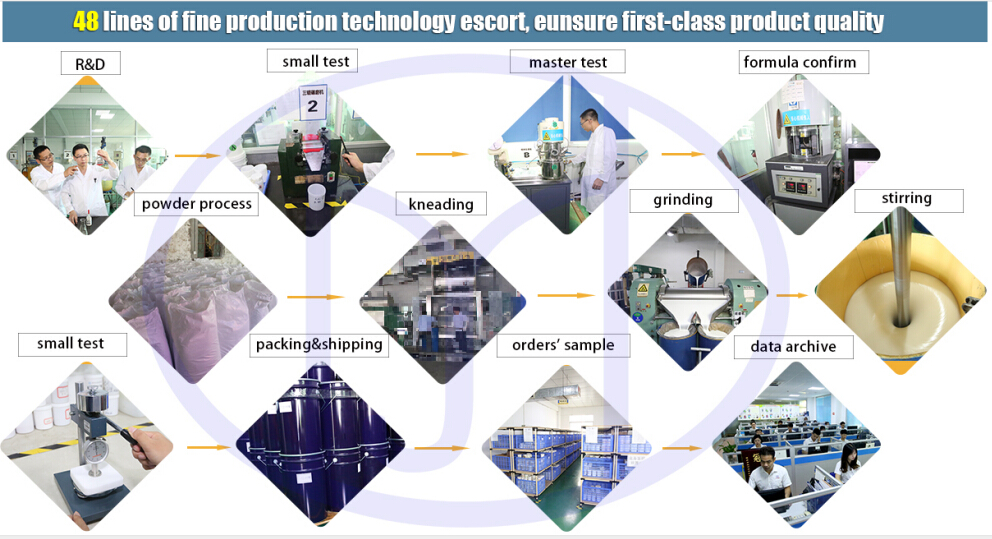

1) 21 years rtv2 silicone factory

2) Return and exchange are accepted while quality problems occurred

3) Exported since 2006

4) Exports to 138 countries

5) 14 years on alibaba.com, 12 years on made-in-china.com, a trustworthy company

6) 12 experts of R&D, QC staffs

7) 6000 square meter factory

8) Free training of silicone technique

9) Free silicone samples

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号