Product No:HY-E series

Brand:HONG YE JIE

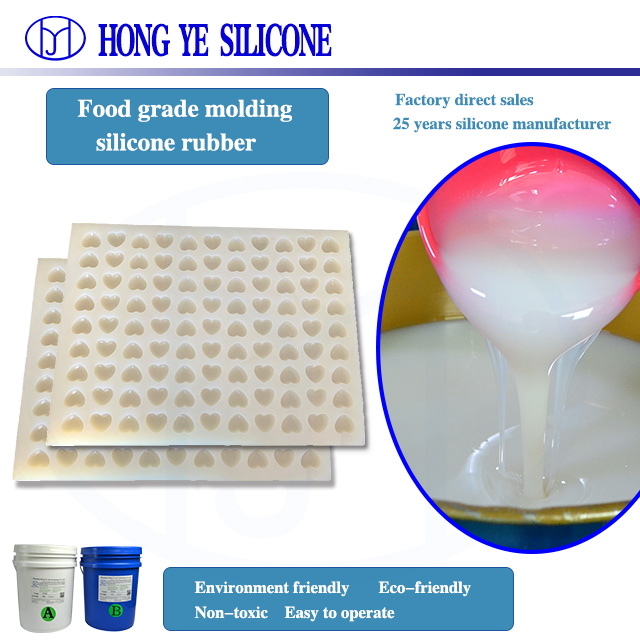

Product Usage:Food grade silicone(also medical grade silicone) is composed of two parts. Part A is a flowable liquid, part B is the curing agent (platinum catalyst). It features an exceptional fluidity and good operability. Because of its high transparency and high tear strength, it is always used for prototyping and all kinds of food mold.

DESCRIPTION OF RTV SILICONE FOR FOOD MOLD MAKING

Food grade silicone(also medical grade silicone) is composed of two parts. Part A is a flowable liquid, part B is the curing agent (platinum catalyst). It features an exceptional fluidity and good operability. Because of its high transparency and high tear strength, it is always used for prototyping and all kinds of food mold.

APPLICATIONS OF RTV SILICONE FOR FOOD MOLD MAKING

• Rapid prototyping (urethane casting/silicone tooling/vacuum casting)

• GRC and concrete molding

• PU resin casting

• General mold making

• Food grade molding application, food safe mold making.

MAIN FEATURES OF RTV SILICONE FOR FOOD MOLD MAKING

- Almost nil shrinkage

- High chemical resistance to aggressive components of some types of resins

- Strong tear strength (this feature ensures higher resistance to wearing and shearing)

- High degree of precision in reproduction

- High dimensional stability over time and non-deformability

- High resistance to high temperatures and ageing (resist to -60 to 200°C)

- Fine surface without being sticky.

- Food grade, FDA approved (environmentally friendly, odorless and nontoxic)

NOTICE OF RTV SILICONE FOR FOOD MOLD MAKING

Hardness is not fixed, you can adjust it in accordance with your actual situation and needs. (silicone oil can not be add too much, otherwise the quality will be ruined)

OPERATION INSTRUCTIONS OF RTV SILICONE FOR FOOD MOLD MAKING

1. Clean the model and molding tool completely before operation to prevent cure inhibition and guarantee flawless quality.

2. Weigh out silicone material appropriately.

3. Mixing the two parts in 1:1/10:1 and stir part A and part B thoroughly to form a kind of even and uniform mixture.

4. And get the mixture for vacuum-pumping for de-air the bubble in around 2-3 minutes. (If there is no vacuum machine, pour the mixture carefully and slowly down the side of the mold frame in case of producing bubbles).

5. Enclose the product (the original model) with four plastic plates or wooden plates.

6. Clean your products and brush a layer of release agent (detergent or soap water) on your product.

7. Pour the vacuumed mixture into the model frame from the side of the mold frame.

8. When curing time is arriving, a FDA approved silicone mold is finished.

As our Q-series silicone is in platinum cure system, which is very easy to cause cure inhibition. So you need to clean the model and tool before operation. Avoid contacting or mixing with the following material, otherwise the platinum cured silicone material won’t be cured:

1. Tin cure silicone rubber material

2. Sulphur, sulfide and sulfur rubber materials.

3. Amine compounds as well as contains the amine materials.

4. Pewter solder flux.

PACKAGE OF RTV SILICONE FOR FOOD MOLD MAKING

20KG/drum vacuum packing for part A + 20KG/drum vacuum packing for part B

200KG/drum packing for part A +200KG/drum packing for part B

SHELF LIFE OF RTV SILICONE FOR FOOD MOLD MAKING

8-10 months when stored under 24℃ in original unopened packages.

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号