Product No:HY-6 series HY-E series

Brand:HONG YE JIE

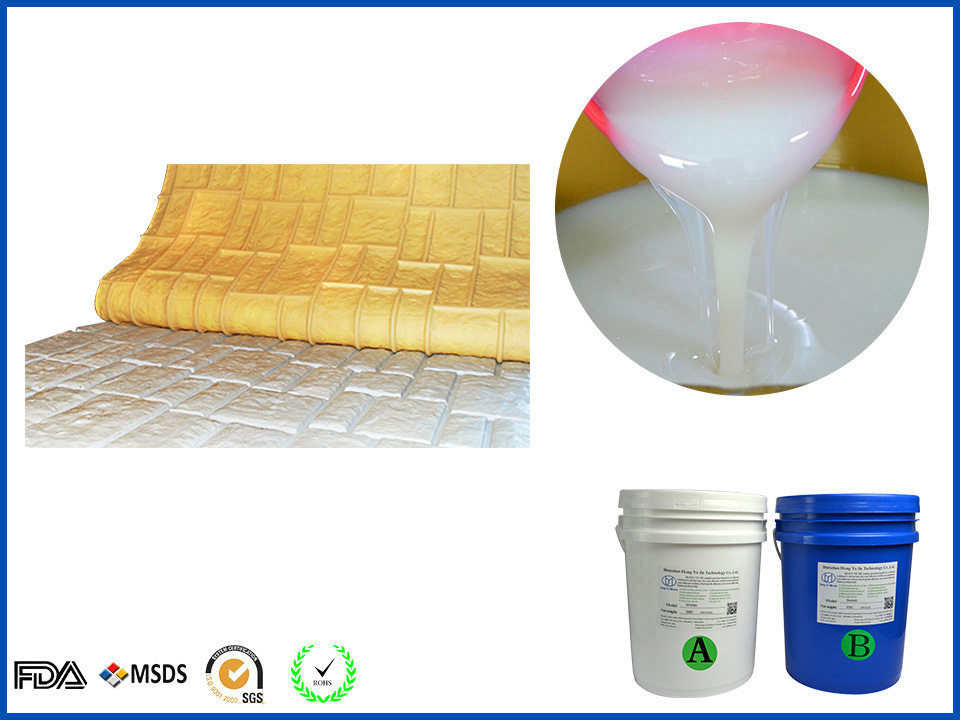

Product Usage:Casting silicone rubber is a kind of two-component molding silicone rubber, consisted of flowable liquid part A and B. which can be cured at room temperature or heated temperature. Casting RTV Silicone has many advantages as below: Good liquidity, easy to operate, high transparency, without being limited by the thickness of the products, excellent temperature resistance and thermal stability and so on.It's suitable for both pouring method and brushing method.

CASTING SILICONE RUBBER FOR MOLDS DESCRIPTION

Casting silicone rubber is a kind of two-component molding silicone rubber, consisted of flowable liquid part A and B. which can be cured at room temperature or heated temperature. Casting RTV Silicone has many advantages as below: Good liquidity, easy to operate, high transparency, without being limited by the thickness of the products, excellent temperature resistance and thermal stability and so on.It’s suitable for both pouring method and brushing method.

CASTING SILICONE RUBBER FOR MOLDS APPLICATION

Casting silicone rubber is mainly used for silicone mould making of a variety of precision parts mold making, such as aerospace parts, auto parts, military supplies, silicone robot molds, fiberglass, ships and other accessories, it also can be used for mold making of a variety of high temperature products.

CASTING SILICONE RUBBER FOR MOLDS CHARACTERISTIC

1. without being limited by the thickness of the products, depth of curing.

2. Has excellent temperature resistance from 300-500 ℃

3. Good tensile strength and tear strength, with a variety of duplication times

4. Has excellent electric properties and chemical stability, resistance to water, ozone abd weathering

5. Low shrinkage (≤0.1%), the crosslinking process don’t release any low molecular weight, so the volume will not changed

6. Good liquidity, easy for pouring; it can be cure at both room temperature or heated temperature , easy- operation.

CASTING SILICONE RUBBER FOR MOLDS OPERATION

1. Mold’s surface cleaning: We can brush or spray the release agent to the surface of the mold, and the release agent or the potting material can be the liquid wax.

2. Mixed: mix the part A and part B( on a weight ratio of 10: 1) by manually or equipment.

3. Pouring the silicone rubber into the frame to cover the model completely with 3cm thickness.

4.Remove air bubbles: We shall Remove air bubbles before pouring the liquid silicone rubber.When a small amount of silicone rubber be use, it can be operated in the vacuum dryer, under vacuum, the volume of rubber foam can increase 4 ~ 5 times, therefore, the volume of the vacuum dryer machine shall be 4 ~ 5 times larger than the volume of rubber, then the volume of silicone material will back to a normal volume in a few minutes, until the surface without air bubbles,(approximately 10 minutes) ,this air bubbles-removed process is completed.

5. Vulcanization and Demould: after mixing and vacuum pumping,the prototype design silicone rubber mold can cured within 30 minutes under 120 ± 5 ℃ baking temperature , or 2 to 3 hours curing under 60 ~ 70 ℃ baking temperature, or 24 hours under room temperature. The curing temperature and curing time can be changed according to the process conditions.

CASTING SILICONE RUBBER FOR MOLDS NOTES 1.Weight part A& part B two components according to the mix ratio 1: 1 then stirring evenly, after vacuum degassing ,it can be poured. The operating time is 30 minutes at room temperature (25℃), and 2-3 hours can be fully cured .when heated to 60-120℃ , it can be completely cured in dozens of minutes. 2. As the addition cure silicone rubber is easy to cause uncured, please clean up all the tools which had mixed with condensation cure silicone rubber before, to avoid the addition cure silicone rubber be uncured. 3. Viscosity, operation time, cured hardness can be adjusted according to the individual requirement.

CASTING SILICONE RUBBER FOR MOLDS PACKAGE

20KG/drum for part A + 20KG/drum for part B

200KG/drum for part A +200KG/drum for part B

CASTING SILICONE RUBBER FOR MOLDS SHELF LIFE

Twelve(12) months when stored under dry and cool place by original package under 25℃

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号