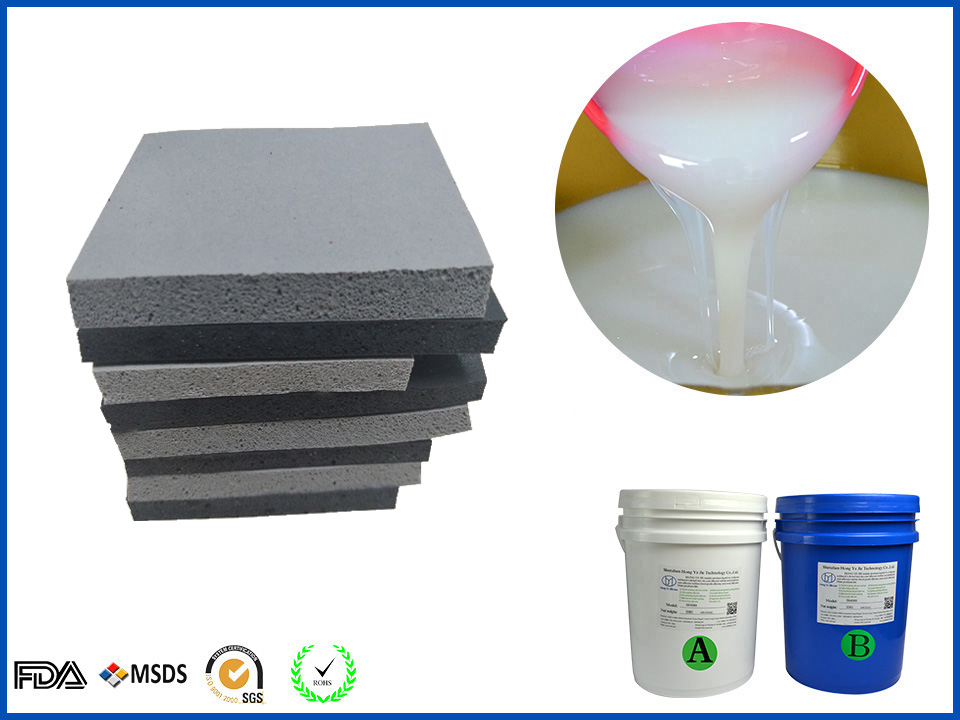

Product No:HY-F

Brand:HONG YE SILICONE

Product Usage:Open cell silicone foam is a soft, two-component platinum silicone flexible foam that is versatile and easy to use. HY-F666 Platinum Silicone Foams expands 6-7 times its original volume and develops a uniform 10 lb./cu. ft. cell structure (150 kg/m3). Vibrant colors can be achieved by adding Silc-Pigsilicone color pigments. Cured foam is high heat resistance (will resist up to 350°F/176°C), water resistant, UV resistant and resists oxidation and ozone degradation.

OPEN CELL SILICONE FOAM DESCRIPTION

Open cell silicone foam is a soft, two-component platinum silicone flexible foam that is versatile and easy to use. HY-F666 Platinum Silicone Foams expands 6-7 times its original volume and develops a uniform 10 lb./cu. ft. cell structure (150 kg/m3). Vibrant colors can be achieved by adding Silc-Pigsilicone color pigments. Cured foam is high heat resistance (will resist up to 350°F/176°C), water resistant, UV resistant and resists oxidation and ozone degradation.

OPEN CELL SILICONE FOAM USAGE

Open cell silicone foam can be used for a variety of industrial and special effects applications including making foam filled appliances, padding/seat cushioning, orthotics/orthopedics, potting and encapsulation of electrical circuits and vibration dampening.

OPEN CELL SILICONE FOAM CHARACTERISTIC

1. Open cell

2. Light

3. Low density

4. High foaming multiple times

5. Low viscocity

6.Very soft

7.Excellent temperature resistence

OPEN CELL SILICONE FOAM POURING, CURING&PREFORMANCE

Warning - A small amount of Hydrogen gas is released as part of the A:B reaction. Use only with adequate ventilation and do not breathe fumes. Also do not smoke or have other ignition sources in proximity to this product during mixing and pouring. Pouring - For best results, pour your mixture in a single spot at the lowest point of the containment field and let the mixture seek its own level. Handling Strength is 20 minutes with full cure in 1 hour at room temperature. Foam color will darken over time. Adding silicone pigments will help stabilize color of cured foam. To adhere Silicone Foams to other platinum silicones, best adhesion is realized when poured against newly cured platinum silicone rubber. Results May Vary: This material is subject to variables such as high or low environmental temperatures. A small test to determine how material performs for your application is recommended.

IMPROVE SURFACE FINISH AND MINIMIZE VOIDS WITH BACK PRESSURE

Use a board that will completely cover the mold opening. Using a ”¾ (2 cm) drill bit, drill 3 holes in the board spaced a few inches / cm apart. Make sure that, when the board is placed over the mold opening, the holes are over the mold cavity and rising foam will be able to make it through. Apply Ease Release 200 thoroughly too both sides of the board and into the drilled holes. Mix and pour foam into mold cavity and place board over mold opening. Hold board firmly in place. As foam rises in the mold cavity, some foam will grow out of the drilled holes. After the foam stops growing, you can let go of the board. Do not demold for at least 20 minutes.

OPEN CELL SILICONE FOAM PACKAGE

Packed in 20kg/pail + 20kg/pail and 200kg/pail + 200kg/pail.

OPEN CELL SILICONE FOAM SHELF LIFE

12 months when stored under 24℃ in original unopened packages.

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号