Product No:HY-E series

Brand:

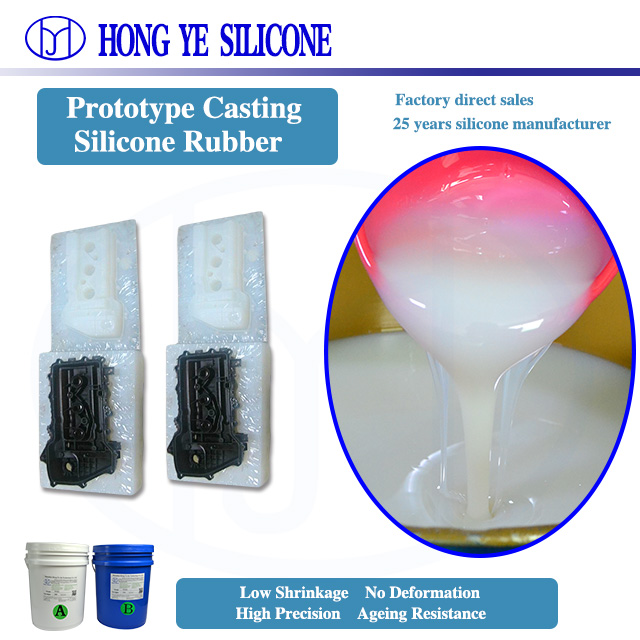

Product Usage:Prototyping moliding silicone rubber is a kind of two part silicone rubber in addition cure or platinum cure type with mixing ratio of 1:1 or 10:1 . It can cure at room temperature as well as under heat . It’s a kind of food grade silicone and mainly used for mold making.

SILICONE RUBBER FOR PROTOTYPING MOLDING & CASTING DESCRIPTION

Prototyping moliding silicone rubber is a kind of two part silicone rubber in addition cure or platinum cure type with mixing ratio of 1:1 or 10:1 . It can cure at room temperature as well as under heat . It’s a kind of food grade silicone and mainly used for mold making.

SILICONE RUBBER FOR PROTOTYPING MOLDING & CASTING APPLICATION

HONG YE JIE's prototyping silicone rubber is not only suitable for making molds for prototyping molding & casting; Also suitable for making modls for chocolate, sugar, cakes, cookies, bread and so on.

SILICONE RUBBER FOR PROTOTYPING MOLDING & CASTING CHARACTERISTICS

1.Good fluidity, good operability, good for pouring method;

2.Excellent mechanical properties, in particular tear strength and tensile strength;

3.Excellent flexibility, easy to demould.

4.High temperature resistance, high duplication times and repeated use.

5. Wide range of catalysts/curing agent/hardener for various applications and various requirements on the operation time or curing time.

6. Good cut-growth resistance;

7. High durometer hardness;

8. Low shrinkage;

9.Easy release;

10.Room temperature cure within 24 hours or Heat-accelerable cure ;

SILICONE RUBBER FOR PROTOTYPING MOLDING & CASTING NOTES

1.RTV addition silicone is widely used in rapid prototyping industry, typically used for making 20 to 40 pieces of functional prototypes out of broad range of polyurethanes and other polymers.silicone tooling is the fastest, most accurate, and least expensive way to create duplicates of a prototype part .

2.As RTV addition silicone is a kind of platinum cure system ,which will be easy to cause uncure problem ,so Kindly follow the tips below :

-Do not mix with liuqid condensation silicone rubber or even the tool which used for condensation silicone

-Do not mix with organic matter which contains N, S, P organics and ionic compound like Sn, As,Hg, Ph,

-Do not add any pigment or powder into the addition cure silicone rubber without any testing to prevent uncure problem

SILICONE RUBBER FOR PROTOTYPING MOLDING & CASTING PACKAGE

20KG/drum vacuum packing for part A + 20KG/drum vacuum packing for part B

200KG/drum packing for part A +200KG/drum packing for part B

SILICONE RUBBER FOR PROTOTYPING MOLDING & CASTING SHELF LIFE

Twelve(12) months when stored under dry and cool place by original package under 25℃

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号