Product No:HY-6 HY-5 HY-EHY-Y8 series

Brand:HONG YE JIE

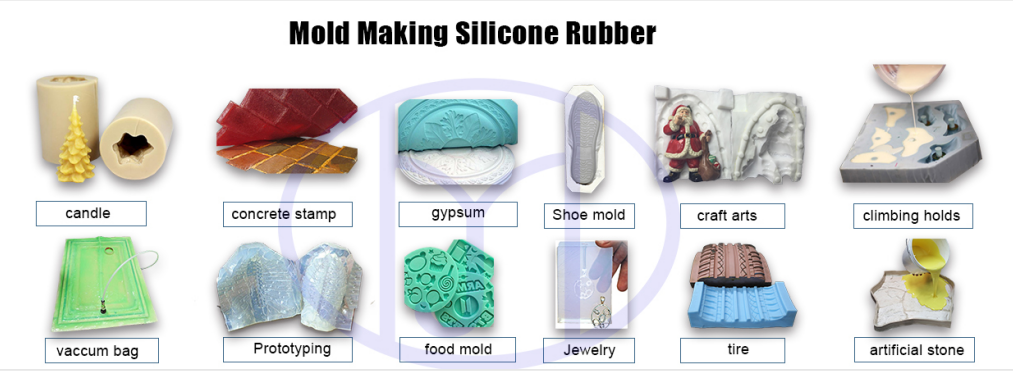

Product Usage:Mouldmaking silicone s used for making moulds for production of parts in various materials: plaster, wax, reconstituted stone, various resins (polyurethane, epoxy, acrylic, polyester),

HONG YE JIE's mould making silicone rubber is also perfect for construction decorative items: cornices, columns, ornaments, statues, artificial stones, plaster mouldings, gypsum ornaments, GRC, GRP, garden decorative, pavement, paving stone, urban furniture., concrete castingand so on.

It's also suitable for molding for arts and crafts, sculpture, figurines, toys, candles, giftware, soap, craft projects, furniture and so on.

DESRIPTION OF MOULD MAKING SILICONE RUBBER

RTV-2 mould making silicone rubber are general called two-component room temperature vulcanization liquid silicone rubber with excellent fluidity and good operational performance. Part A is liquid silicone, part B is curing agent.

HONG YE JIE's mould making silicone rubber includes tin cure silicone and platinum cure silicone, we also call them condensation cure silicone and addition cure silicone.

APPLICTION OF MOULD MAKING SILICONE RUBBER

This liquid silicone material specially suitable for mould making perfectly due to its high tear and tensile strength.

Mouldmaking silicone s used for making moulds for production of parts in various materials: plaster, wax, reconstituted stone, various resins (polyurethane, epoxy, acrylic, polyester),

HONG YE JIE's mould making silicone rubber is also perfect for construction decorative items: cornices, columns, ornaments, statues, artificial stones, plaster mouldings, gypsum ornaments, GRC, GRP, garden decorative, pavement, paving stone, urban furniture., concrete castingand so on.

It's also suitable for molding for arts and crafts, sculpture, figurines, toys, candles, giftware, soap, craft projects, furniture and so on.

FEATURES OF MOULD MAKING SILICONE RUBBER

1. No deformation,Excellenttear strength and tensile strength

2. High resist to alkali & flexion

3. Highly flexible and resilient

3. Good fluidity and good operability and good for both pouring method and pouring method.

5. Excellent UV-irradiation resistance and aging resistance

6. Low shrinkage

OPERATION OF MOULD MAKING SILICONE RUBBER

Firstly, Mix part A and part B evenly according to the mixing ratio of 100:2 or 100:5 and can be poured after deair the bubbles. The operating time depends on the temperature; The curing time is 15-30 mins at the room temperature; And the curing time can be reduced to 10 minutes with the temperature increased to 80~120°C. The operating time of the room temperature quick drying type is less than 20 minutes and the curing time is 0.5 hour. The product can be produced in skin color, yellow, etc. According to the customer's requirements.

NOTES OF MOULD MAKING SILICONE RUBBER

1.The curing rate of this product is closely relevant to the temperature. The higher the temperature is, the greater the humidity is and the curing speed becomes faster.

2.Users can choose the curing agent according to the weather condition, and adjust the amount of the curing agent in order to reach the appropriated curing rate.

SHELF LIFE OF MOULD MAKING SILICONE RUBBER

Twelve(12) months from date of shipment when stored under 25℃ in the original sealed packages at dry and cool places.

PACKAGE OF MOULD MAKING SILICONE RUBBER

1kg/jar, 5kgs/drum, 20kgs/drum, 25kgs/drum, 200kgs/drum and vacuumed packing is available.

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号