Product No:HY-9 series

Brand:HONG YE JIE

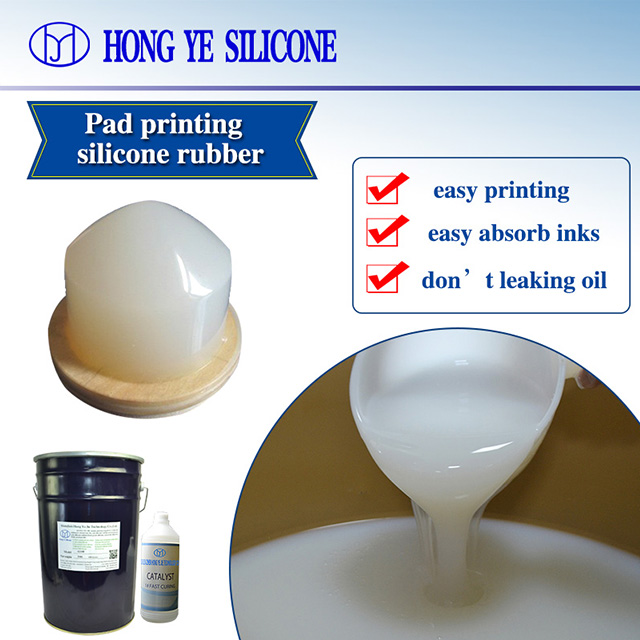

Product Usage:Pad printing silicone rubber is applicable to produce silicone printing pads (silicone transfer pads) , Which is used for printing the irregular patterns on plastic toys, ceramic products, aluminum alloy sheet, electroplating products, trademarks, artworks and stationery etc.The silicone pad is a carrier which transfers the patterns from the steel plate onto the product’s surface.

SILICONE RUBBER FOR MAKING PRINTING PAD APPLICATION

Pad printing silicone rubber is applicable to produce silicone printing pads (silicone transfer pads) , Which is used for printing the irregular patterns on plastic toys, ceramic products, aluminum alloy sheet, electroplating products, trademarks, artworks and stationery etc.The silicone pad is a carrier which transfers the patterns from the steel plate onto the product’s surface.

SILICONE RUBBER FOR MAKING PRINTING PAD DESCRIPTION

Pad printing silicone rubber is kinds of RTV-2 liquid silicone rubber with excellent fluidity and good operational performance,it includes platinum cure type and tin cure type. Its function is to pick up the image from the steel plate (cliche) and then transfer it to the product of almost any convex , concave, regular ,irregular ,or flat surface.

SILICONE RUBBER FOR MAKING PRINTING PAD ADVANTAGES

- Thousands of printing times, high quality

- Excellent printing effects

- Excellent resilience

- Without any impurity

- Multiple hardness

SILICONE RUBBER FOR MAKING PRINTING PAD MAKING INSTRUCTION

Step 1: Prepare the original silicone pad pvc molds, make sure your original molds smooth and Clear.

Step2: Mix part A liquid silicone and silicone oil.

Usually the original hardness of the silicone pad is around 28 shore A , but adding silicone to adjust the hardness is available, when adding 2% silicone oil , the hardness will reduce 2 shore A. For example HY-933 silicone is 28 shore A , if you require hardness of 25 shore A for printing , then add 6% silicone oil .The percentage of silicone oil added should not more than 30% to keep high quality.

Step3:Add catalyst (part B) into the mixture and mix them evenly.

After the Step 2 by adding and mix the silicone oil evenly ,add the catalyst with recommended mixing raio into the mixture (For example, if the recommended mixing ratio is 5%, then this 5% is the weight of the totally mixture of liquid silicone and silicone oil ) and mix them evenly .

Notes: A. Weigh the exactly weight by electronic weight.If add two much catalyst , the operation time will be too fast to operate ,which will cause inconvenience to operate .

B. Mixture should stir evenly. Otherwise the silicon rubber will be partly solidified and this will give birth to difficulties in your final operation. What’s more, the finished silicone pad will meet a short life.

Step4: Vacuum pumping

This step takes less than 10 minutes. Otherwise, it will cause cross linking reaction, and no more further steps will be available.

Step 5: Pouring the mixture into the original PVC mold

Notes: A. Put an wooden board on the surface of the silicone pad and set an hole on the board to make sure the board will closely stick on the pad .

B. Wait till the silicone pad totally cured before put into production.

SILICONE RUBBER FOR MAKING PRINTING PAD PACKAGE

1 kg/jar, 5 kg/drum, 20 kg/drum, 200 kg/drum and vacuum package is available.

SILICONE RUBBER FOR MAKING PRINTING PAD SHELF LIFE

Twelve(12) months when stored under dry & cool place by original package under 25℃.

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号