Product No:HY-6 HY-5 HY-E HY-Y8 series

Brand:HONG YE JIE

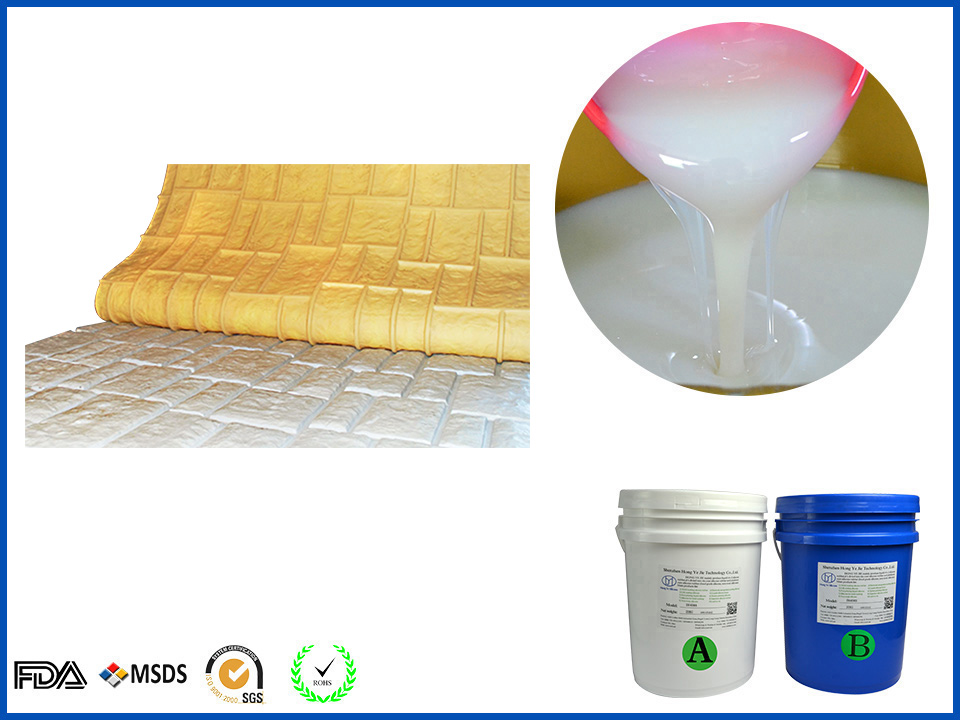

Product Usage:Artificial stone mold silicone rubber is used to duplicated for artificial stone.In generalits hardness is slightly higher, the suitable hardness is 30 to 40 shore Awhich is fit for condensation cure and addition cure silicone rubber.

DESCRIPTION

Artificial stone mold silicone rubber is used to duplicated for artificial stone.In general,its hardness is slightly higher,the suitable hardness is 30 to 40 shore A,which is fit for condensation cure and addition cure silicone rubber.

The cost of condensation cure silicone rubber is cheaper.Due to addition cure silicone rubber is food-grade silicone rubber with non-toxic,tasteless and environmental,the price is slightly higher,each takes what you need.

Artificial stone mold silicone rubber is also a kind of ordinary liquid bicomponent silicone rubber,part A is liquid silicone rubber,part B is curing agent,according to mixing ratio to mix part A and part B,then you will get the finished products. The higher hardness of silicone rubber,the hardness of silicone mould will be higher,when it is used for cement,the mould will not be easy to deform with have high tear strength and good flexibility.Therefor,mold silicone rubber is the best material to duplicate cement products.

APPLICATION

Artificial stone mold silicone rubber is specially intended for furniture architectural decoration of big stone,gypsum,cement,artificial stone,roman column,stone carving,and so on.It is also suitable for crafts and ornaments of simulated animal and plant sculpture,resin,plaster,polyester,buddhist statue,etc.

FEATURES

1.High tensile and tear strength,non-deformation,suitable for artificial stone.

2.Good flexibility,easy demoulding,the product will not be damaging when demoulding.

3.Flowability is easy to debug:pouring with low viscosity,good fluidity and easy to release bubbles.brushing easily with adjustable viscosity.

4.High and low temperature resistance,acid and alkali resistance,non-expansion,in favor of repeated using mould.

5.Lower shrinkage on the market,have better contractility after adding fiberglass cloth.

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号