Product No:HY-9 series

Brand:HONG YE JIE

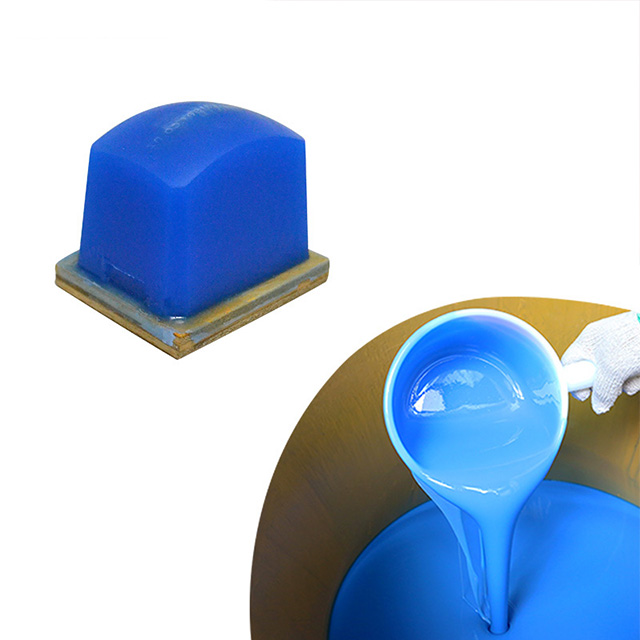

Product Usage: The liquid pad printing making silicone rubber is with the advantages of high temperature resistance abrasion resistance good printing effect etc.which made of top-quality raw material due to adding American Dupont Teflon high-temperature resistance new material is processed through high-temperature machining.The product can be used to make high-quality silicone tampo print pad which is mainly applicable to plastic toys electroplating products electronic toys trademarks and irregular pattern printing. The silicone rubber pad is a carrier which transfer printing the patterns on the steel plate onto the toy products' surface.

DESCRIPTION of PAD PRINTING SILICONE FOR PLASTIC TOYS

The silicone pad which is made from silicone rubber will have around 15-35 shore A hardness, neither too hard nor too soft. The liquid pad printing making silicone rubber is with the advantages of high temperature resistance, abrasion resistance, good printing effect, etc.which made of top-quality raw material due to adding American Dupont Teflon high-temperature resistance new material, is processed through high-temperature machining.The product can be used to make high-quality silicone tampo print pad, which is mainly applicable to plastic toys, electroplating products, electronic toys, trademarks and irregular pattern printing. The silicone rubber pad is a carrier which transfer printing the patterns on the steel plate onto the toy products' surface.

OPERATION INSTRUCTION of PAD PRINTING SILICONE FOR PLASTIC TOYS

1.Fully clean the prepared mold and dry the mold with an air gun(also you can dry it by wiping it with a clean cloth).

2.Spray some release agent on the surface of the mold.

3.The ratio of silicone an silicone oil depends on actual demands. If you need soft printing pad, then you could add more silicone oil.Otherwise you can add no or less. Normally,the hardness range from 15 A° to 25 A° is appropriate.

4. Do not add too much silicone oil, it will ruin the silicone pad.

PACKAGE of PAD PRINTING SILICONE FOR PLASTIC TOYS

20KG/drum or 25KG/drum or 200KG/drum for part A +1kg/ bottle catalyst for part B

SHELF LIFE of PAD PRINTING SILICONE FOR PLASTIC TOYS

TWELVE (12) months when stored under dry and cool place by original package under 25℃.

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号