Product No:HY-2 HY-90 HY-93 series

Brand:HONG YE JIE

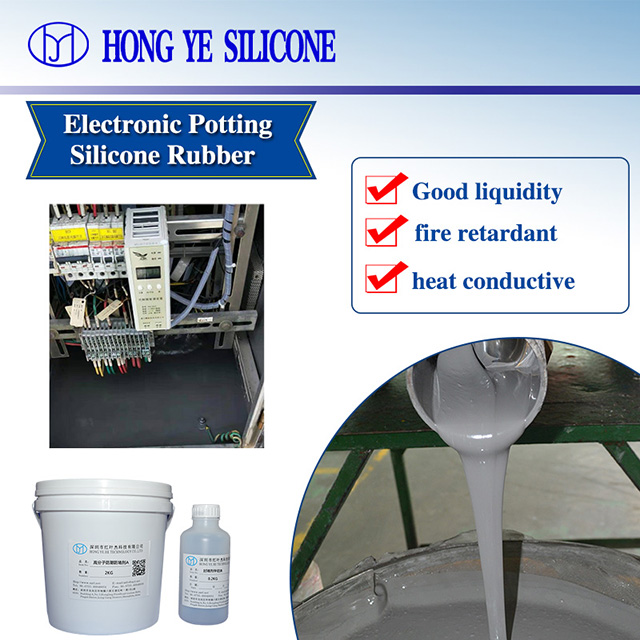

Product Usage:Encapsulant potting compound is a kind of condensation cure silicone in two parts with the characteristics of strong adhesion excellent thermal conductivity good moisture protection high temperature resistance. It can be cured completely at room temperature. The safety of this RTV encapsulation material can reach the EU-ROHS requirements fully.

DESCRIPTION OF ENCAPSULANT SILICONE

Encapsulant potting compound is a kind of condensation cure silicone in two parts with the characteristics of strong adhesion, excellent thermal conductivity, good moisture protection, high temperature resistance. It can be cured completely at room temperature. The safety of this RTV encapsulation material can reach the EU-ROHS requirements fully.

USAGE OF ENCAPSULANT SILICONE

- Applying for the surface of PC (Poly-carbonate), PP, ABS, PV, photovoltaic cell, PVC, metal,etc.

-Encapsulation for protection of general electronic module, electronic components -Insulation, waterproof and bonding of electronic parts

-Bonding, Sealing(as a sealant or adhesive) for LED, LCD electronic display, circuit board, automobile component

-Outdoor protection for LED screen

USING NOTE OF ENCAPSULANT SILICONE

1. All the data is based on the condition of 25℃ with 55% humidity.

2. Sealing package for storage. The mixture should be used up at once to avoid wasting.

3. Dot not let the liquid go into mouth and eyes when operate the potting process.

4. When it gets stratified after a period of storage, you should mix the electronic silicone rubber evenly before using, it does not affect the performance(before the expiration date). 5. It can be stored for 12 months at 24℃ in original unopened packages.

TECHNICAL GUIDELINES OF ENCAPSULANT SILICONE

1. Please put part A and B in separate container and stirs evenly before mixing the two parts together.

2. Weight Ratio: part A: part B = 10:1

3.Bubble release if necessary, Deaeration the mixture under 0.08 MPa for 3 minutes.

4. HY 215 is cured at room temperature, so please put it under room temperature after pouring. It comes to next process when basically cured, and it takes about 24 hours for completely cured.(Temperature and humidity will influence the curing of HY215.)

PACKAGE OF ENCAPSULANT SILICONE

25KG/drum vacuum packing for part A +1kg/ bottle catalyst for part B

200KG/drum packing for part A +1kg/ bottle catalyst for part B

SHELF LIFE OF ENCAPSULANT SILICONE

Twelve(12) months when stored under dry and cool place by original package under 25℃

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号