Product No:HY-2 HY-90 HY-93 series

Brand:HONG YE JIE

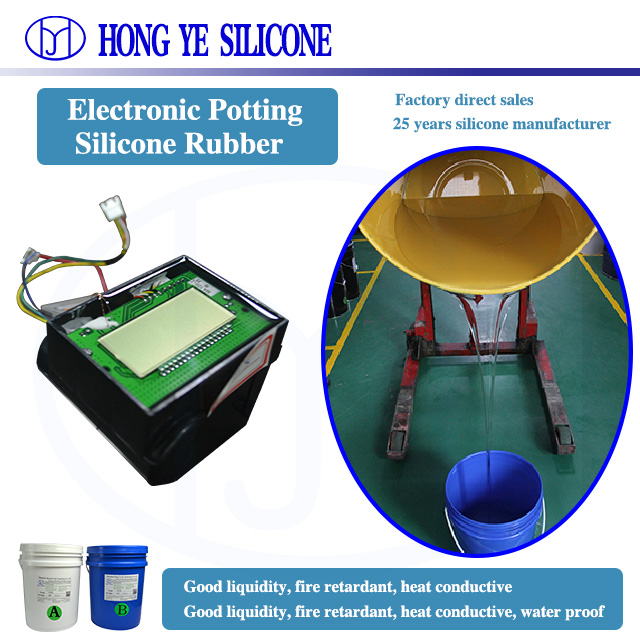

Product Usage:Transparent waterproof potting compound is a kind of two components (1:1mixing ratio) addition cure silicone with the Characteristics of heat-conducting low viscosity Inherent flame resistance waterproofing etc. It can cure both at room temperature and heated temperature and the curing time can be accelerated by higher temperature.

TRANSPARENT WATERPROOF POTTING COMPOUND DESCRIPTION

Transparent waterproof potting compound is a kind of two components (1:1mixing ratio) addition cure silicone with the Characteristics of heat-conducting, low viscosity, Inherent flame resistance, waterproofing, etc. It can cure both at room temperature and heated temperature and the curing time can be accelerated by higher temperature.

TRANSPARENT WATERPROOF POTTING COMPOUND APPLICATION

•Applying for the surface of PC (Poly-carbonate), PP, ABS, PVC, Metal, etc.

• High powered electronic encapsulation and DC/DC module and circuit board which requires heat dissipation and high temperature resistance.

• Insulation, waterproof and bonding of general electronic components.

• Filling for LED, LCD electronic display, circuit board, PCB substrate, etc.

• Outdoor protection for LED screen.

TRANSPARENT WATERPROOF POTTING COMPOUND NOTES AND OPERATION INSTRUCTIONS

1) The following material may hinder the curing of potting compound silicone, so please use after the test. When necessary, please clean the application areas.

- Organotin compound or Condensation silicone with organotin

- Sulphur, sulfide and sulfur rubber materials.

- Amine compounds as well as contains the amine materials.

- Pewters solder flux

2) Deaeration the mixture in vacuum pump under 0.08 MPa for 3-5 minutes.Then the mixture could be used for pouring.

3) Please note that the thickness of the silicone affects the curing time. If the silicone used is a little thick, then the curing time will be a little longer. The temperature also affects the curing time. When in lower temperature, we suggest customers appropriately heat the mixture to accelerate vulcanization.

4) Above electronic potting silicone should be sealed storage. The mixture should be used up to avoid causing waste.

5) Above silicone belongs to non-dangerous goods, but keep away from mouth and eyes.

6) When it gets stratified after a period of storage, please mix it evenly before using, this does not affect the performance.

TRANSPARENT WATERPROOF POTTING COMPOUND PACKAGING

Standard packing for potting compound silicone is 22kg/set (Part A 20kg + Part B 2kg)

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号